Cleaning solutions for industrial applications – we are specialists in cleaning processes

The idea of manufacturing industrial cleaning equipment was developed in our craftsmanship division. In fact, there is a lot of craftsmanship in each of our machines and we are proud of every plant that is created in our workshop.

We accompany our customers from the idea, through cleaning tests, the creation of concepts and drawings, to the manufacturing of the equipment. During the manufacturing process, we benefit from our many years of experience in the field of mechanical engineering. Our employees come from different trades and each one is an expert in his field.

Customized solutions

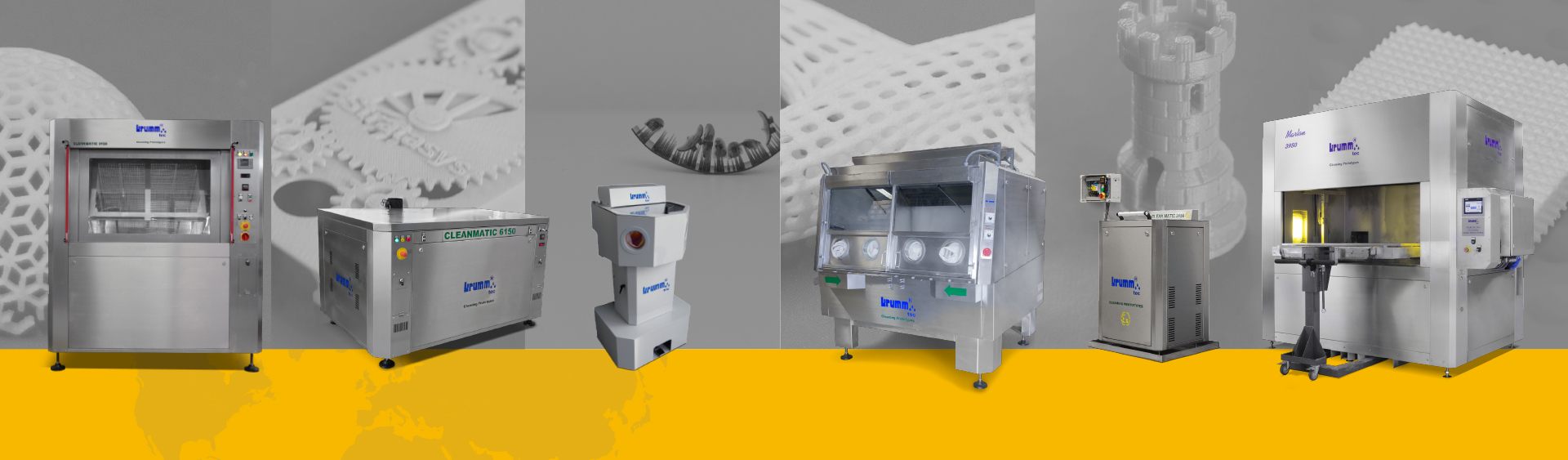

Numerous customers do not find a suitable solution in our standard program. This may be because the required process is too special, integration into existing processes is required, or several cleaning stations should be accommodated in a single system. Or perhaps it is simply because a customized solution is required. In this case, we as a manufacturer can fall back on existing systems, which are then modified in relation to the project in order to optimally meet the customer’s requirements. From small table-top units, to floor-standing units, to cleaning lines with numerous cleaning stations over several meters in length, or large-scale systems the size of a room – with us you will find the right system for almost any process.

krumm-tec RK 30 with sensor-monitored doors left and right, supply air spigot, double diaphragm pump and foot switch. For use with solvent.

krumm-tec RK 30 in powder-coated steel with a door for inserting and removing parts, LED lighting, and coupling to a dust collection system. Cleaning system for dry cleaning and blowing off dust.

krumm-tec RK 30 in blue powder-coated steel with air inlet, a door for inserting and removing parts, LED lighting and connection to a dust collection system. The unit was designed to remove dust and machining residues from workpieces.